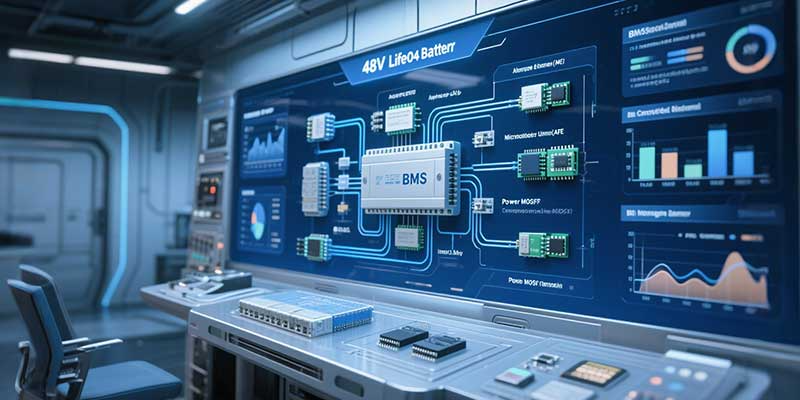

The Battery BMS Design with Dual Circuits

A dual-circuit BMS (Battery Management System) refers to a battery management system that utilizes two separate, independent circuits to manage and protect a battery pack. These circuits are typically designed to handle battery monitoring, protection, charging, and discharging etc., with dual circuit enhance the overall performance, safety, and reliability of the system.

Key Characteristics of a Dual-Circuit BMS:

1.Redundancy:

A dual-circuit BMS provides redundancy, meaning that if one circuit fails, the other can take over, ensuring that the battery system continues to function properly. This is especially important for critical applications where failure is not an option (e.g., electric vehicles, drones, or medical equipment).

By having two circuits that are identical in function, the overall reliability of the system is increased. The backup circuit ensures continuous operation even in the event of a failure in the primary circuit. For example, if one circuit fails due to a hardware issue, the other circuit can still manage the battery, preventing catastrophic failures.

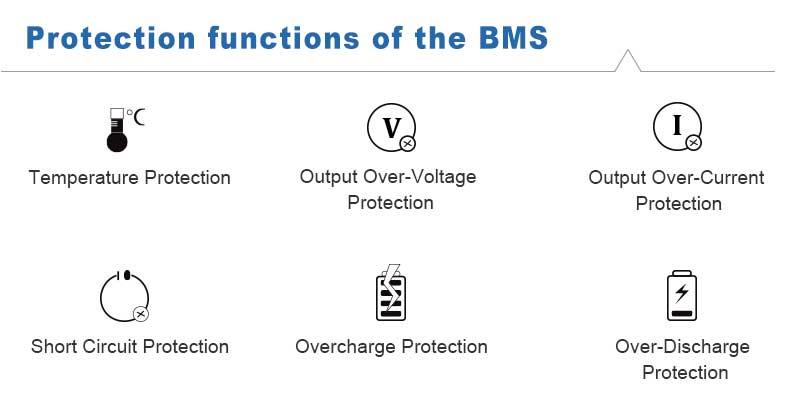

2.Increased Safety and Fault Tolerance:

With two independent circuits, the system is less vulnerable to failure since the malfunction of one circuit doesn’t necessarily lead to a complete system failure. This is crucial in high-reliability applications, where a backup system is needed to maintain operation in case of an issue.

3.Improved System Stability:

By having two circuits dedicated to specific tasks, the overall system becomes more stable because each circuit can be optimized for its function without interfering with the other. This leads to more accurate battery monitoring, better protection mechanisms, and more efficient energy management.

4.Improved Reliability:

By having two circuits that are identical in function, the overall reliability of the system is increased. The backup circuit ensures continuous operation even in the event of a failure in the primary circuit. For example, if one circuit fails due to a hardware issue, the other circuit can still manage the battery, preventing catastrophic failures.

5.Failover Protection:

This design is essentially a failover strategy. The system constantly monitors the status of each circuit, and if one circuit experiences issues (such as a malfunctioning component), the other circuit automatically takes over its duties. This is critical in environments where system uptime is essential.

6.Simplicity:

While a dual-circuit BMS with the same functions is more straightforward than a system with split tasks, it still requires careful design to ensure that both circuits are synchronized properly and do not conflict with one another. The complexity here lies in managing the two circuits so they can seamlessly switch roles in case of failure.

Disadvantages of Dual-Circuit BMS Design:

1.Increased Cost:

A dual-circuit design requires additional hardware components, which raises the material and design costs. Moreover, the complexity of designing and manufacturing two circuits makes the overall system more expensive.

2.Larger Space Requirements:

Due to the additional circuit, dual-circuit BMS systems generally require more space, which could be a challenge for applications with limited space, such as small drones or electric tools.

3.Power Consumption:

Running two circuits simultaneously can lead to additional power consumption. This is particularly important for applications that require long standby times, such as electric vehicles’ battery management systems, where increased power consumption may reduce system efficiency.

4.Maintenance and Debugging Complexity:

Troubleshooting and maintaining a dual-circuit BMS is more complex than a single-circuit system. Handling the coordination between the two circuits and diagnosing issues when they arise can be more challenging.

A dual-circuit BMS design is suitable for applications that demand high levels of safety, reliability, and fault tolerance, such as large battery packs or critical mission devices. While it increases costs and space requirements, its advantages typically outweigh the disadvantages in high-performance or safety-critical environments. The decision should be based on the specific application and a careful balance of these factors.

Applications of Dual-Circuit BMS:

Dual-circuit BMS designs are commonly used in applications where:

—For the high reliability is crucial (e.g., electric vehicles, aerospace, medical devices).

—For safety is a top priority, and the system cannot afford to fail (e.g., critical backup systems, military applications).

—For large battery systems require robust protection and management, such as large-scale energy storage or industrial equipment.

In essence, a dual-circuit BMS ensures that the battery is monitored and controlled with increased precision and security, making it suitable for demanding and mission-critical applications.