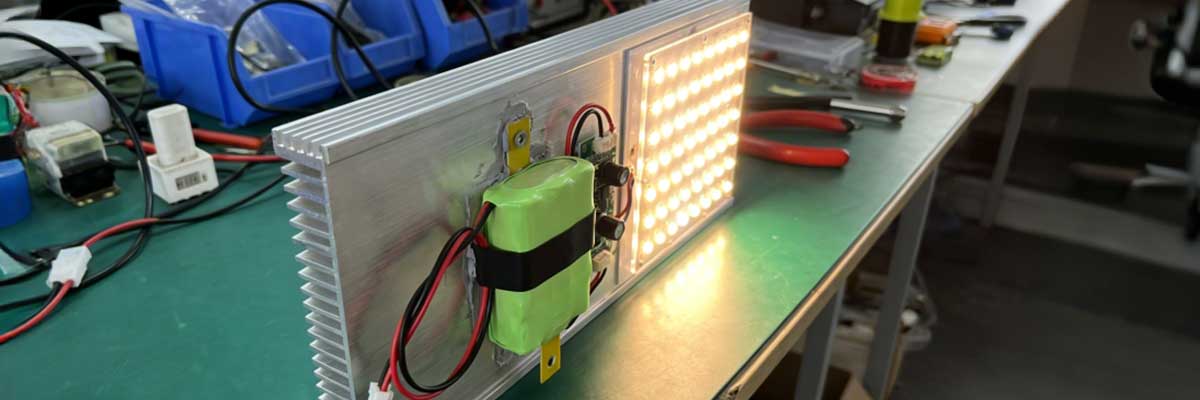

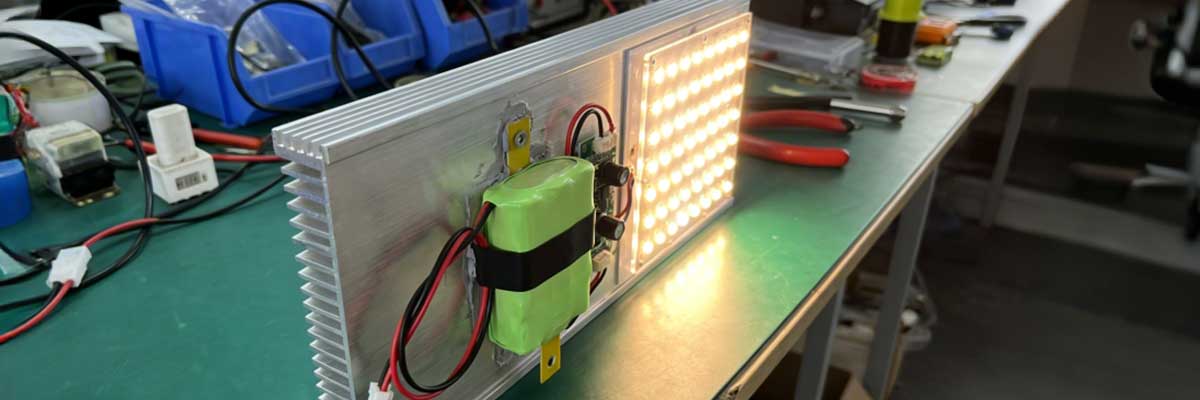

A typical challenge: a battery mounted directly behind an LED light board

Imagine a high-brightness LED lamp with a built-in backup battery.

For design reasons, the battery must sit directly behind the LED board, exposed to continuous heat during long operating hours.

For a standard battery, this situation is extremely problematic:

- Elevated temperature accelerates chemical aging

- Capacity fades rapidly

- Internal resistance increases

- In the worst case, safety margins are compromised

This is not an isolated case.

Many products face similar challenges:

- Internal heat sources such as LEDs, motors, processors, and power electronics

- External environments such as outdoor summer heat, direct sunlight, or freezing winter conditions

In reality, batteries rarely live in “comfortable” conditions.

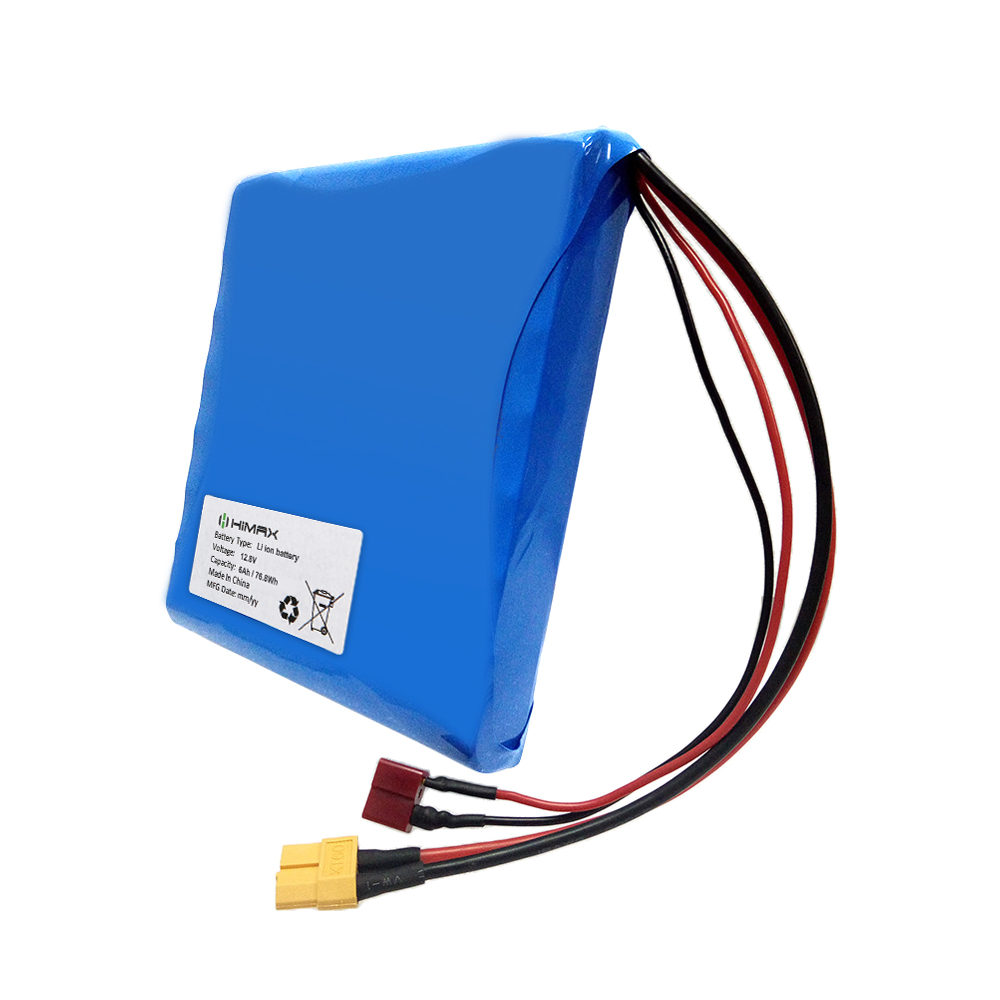

Our core philosophy: no single solution fits all

At Himax, we don’t believe in one “magic” high-temperature or low-temperature battery.

Instead, we act like a battery general practitioner:

- First, we diagnose the source, level, and duration of thermal stress

- Then, we select the most suitable battery chemistry

- Finally, we combine it with system-level thermal and control strategies

Only this combination creates a truly reliable temperature-resistant solution.

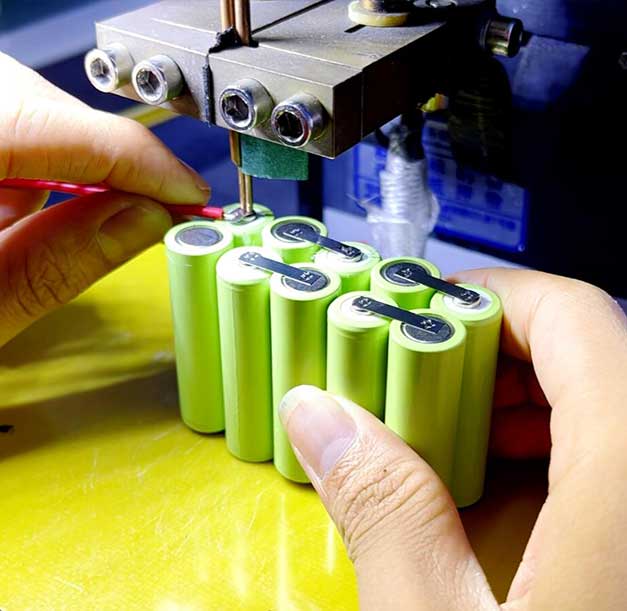

Step one: choosing the right “constitution” — battery chemistry matters

High-temperature environments: starting with the LED case

In applications like LED backboards, the battery is exposed to continuous medium-to-high temperature, not short spikes.

Depending on the design constraints, we may consider different options:

- High-temperature–optimized NiMH batteries

O Naturally tolerant to elevated temperatures

O Very stable and safe below ~60 °C

O Often suitable for standby or backup power in lighting systems

- Special high-temperature lithium-ion batteries

O Use modified electrolytes and electrode formulations

O Provide higher energy density than NiMH

O Suitable when space and weight are limited, but thermal exposure is well understood

The decision is based on measured board temperature, heat duration, required capacity, and expected service life—not on chemistry preference.

Expanding to broader scenarios: heat and cold in the real world

Different thermal challenges require different “tools”:

- Short-term high peak temperature or high power draw

→ High-rate lithium-ion power cells designed to tolerate transient heat

- Hot outdoor environments (solar devices, outdoor electronics)

→ Thermally stable lithium-ion or LiFePO₄ solutions with conservative derating

- Cold environments (outdoor monitoring, winter equipment)

→ Low-temperature–optimized lithium-ion or low-temperature LiFePO₄, ensuring acceptable cold-start performance

There is no universally “best” chemistry.

There is only the chemistry best matched to your temperature profile.

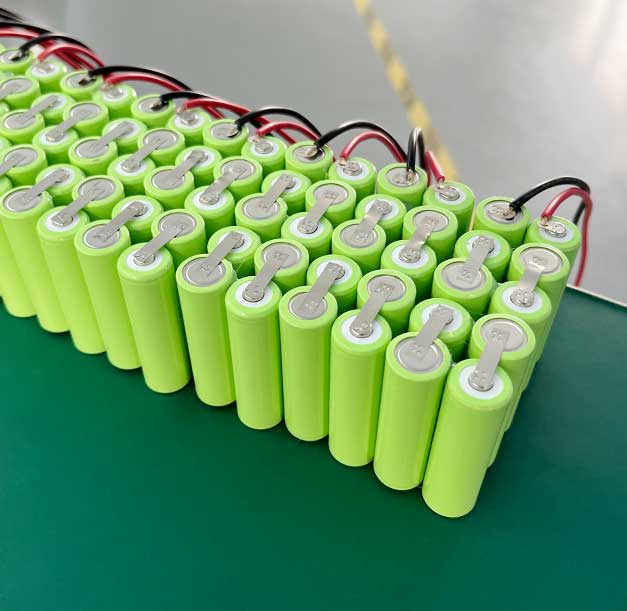

Step two: system-level thermal engineering — creating a buffer zone

Selecting the right chemistry is only half the solution.

We then engineer the system so the cell experiences a more stable micro-climate.

In the LED battery case, this may include:

- Thermal interface materialsbetween the LED board and the battery

(to block radiant heat while spreading residual heat away)

- Strategic placement of insulation and conductive layers

- Mechanical spacing that reduces direct thermal coupling

For outdoor and industrial products, we also consider:

- Insulating or reflective enclosure coatings

- Heat-dissipation structures and airflow paths

- In cold environments, passive insulation or low-power active preheating

Our objective is always the same:

keep the actual cell temperature within its optimal and safe operating window.

Step three: intelligent control and real-world validation

True temperature resistance requires active management and proof.

On the control side:

- Our BMS integrates high-accuracy temperature sensing

- At high temperatures, it can reduce current or power to protect the cells

- At low temperatures, it can enable controlled self-heating or charging limitation

On the validation side:

- Every customized solution is tested through:

O High-temperature aging

O Low-temperature cycling

O Thermal shock

O Extended temperature cycling tests

We don’t rely on theory alone.

We rely on data collected under real stress conditions.

Temperature resistance as a competitive advantage

What we ultimately deliver is not just a “high-temperature battery” or a “low-temperature battery”.

We deliver a validated energy subsystem, deeply matched to:

- Your product’s heat sources

- Its operating environment

- Its lifetime expectations

At Himax, our temperature-resilient battery solutions help you:

- Avoid premature failures

- Reduce warranty and service costs

- Expand into harsher application environments

- Strengthen long-term brand reliability

Let’s address temperature early—together

If your current product is suffering from heat or cold-related battery issues,

or if you are designing a new product intended for extreme environments,

we strongly recommend addressing temperature early in the design phase.

At Himax Electronics, we can support you from:

- Chemistry selection and thermal analysis

- To mechanical design and control strategy

- To prototype testing and validation

We look forward to helping your product perform reliably—no matter the climate.