18650 vs. 26650: Two Classic Cylindrical Lithium Batteries — How to Choose the Right One

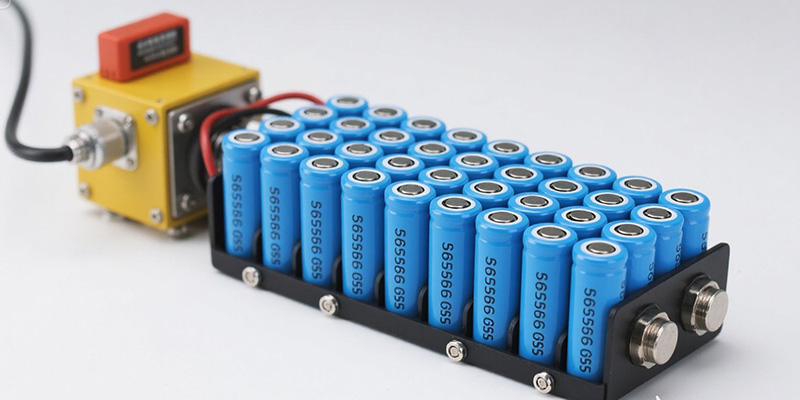

In the world of cylindrical lithium-ion batteries, 18650 and 26650 are two of the most well-known and widely used formats. They have been on the market for many years and are still essential in many industries today.

The numbers in their names act like an “ID card”:

The first two digits indicate the diameter (in millimeters)

The next two digits indicate the length (in millimeters)

The final “0” means the battery is cylindrical

For example:

18650 = 18 mm diameter, 65 mm length

26650 = 26 mm diameter, 65 mm length

Although they share the same length, the 8 mm difference in diameter leads to clear differences in capacity, performance, cost, and application. Understanding these differences is a key step in designing efficient and reliable battery-powered products.

1. Key Differences: More Than Just Size

The table below highlights the main differences between 18650 and 26650 lithium-ion batteries.

Physical Size

18650:

Diameter: 18 mm

Length: 65 mm

26650:

Diameter: 26 mm

Length: 65 mm

Both batteries have the same height, but the larger diameter of the 26650 gives it more internal volume and higher weight, which directly affects capacity.

Typical Capacity

18650:

Common range: 1,800 mAh – 3,500 mAh

26650:

Common range: 4,500 mAh – 5,000 mAh

Under the same battery chemistry, a 26650 cell usually offers more than 50% higher capacity than an 18650 cell, simply because it is larger.

Energy Density

18650: Higher energy density

26650: Lower energy density (compared to 18650)

The 18650 format has been produced on a massive scale for many years. Its manufacturing process is extremely mature and highly standardized, which allows it to achieve better energy density per unit volume.

Discharge Performance

18650:

Very wide range

From standard cells (around 3C) to high-power cells (10C or higher)

26650:

Usually moderate discharge rates

Most models focus on 1C–3C continuous discharge

The 18650 market offers more high-rate power cells, making it suitable for applications that require strong current output.

The 26650 focuses more on a balance between capacity and stable continuous discharge.

Cost and Market Availability

18650:

Lower cost

Extremely widely available

Many brands and suppliers

26650:

Higher cost per cell

Fewer manufacturers and options

The 18650 is an industry-standard cell. Large-scale production creates strong cost advantages.

In comparison, the 26650 supply chain is smaller, which affects both price and availability.

Typical Applications

18650 batteries are commonly used in:

Laptops

Power tools

High-end flashlights

Drones

Electric bicycles and scooters

26650 batteries are commonly used in:

Solar street lights

Energy storage systems

UPS systems

Telecom backup power

Large lighting equipment

In simple terms:

18650 = flexibility and performance

26650 = capacity and durability

2. Shared Advantages: Why They Remain Popular

Despite their differences, both 18650 and 26650 batteries share the core advantages of high-quality cylindrical lithium-ion cells:

High energy density compared with NiMH or lead-acid batteries

Long cycle life, often more than 500 cycles to 80% capacity

No memory effect, allowing flexible charging

Stable nominal voltage (typically 3.6V–3.7V)

Easy pack assembly, as cylindrical cells are easy to connect in series and parallel using holders or brackets

These advantages make them reliable building blocks for battery packs of many sizes and voltage levels.

3. Inherent Limitations: What System Design Must Address

Both formats also share some limitations that designers must consider:

Fixed shape

Cylindrical cells cannot fully use irregular internal space, unlike pouch batteries

Protection required

A protection circuit or battery management system (BMS) is essential to prevent overcharge, over-discharge, over current and short circuits.

Safety design challenges

In extreme thermal runaway cases, cylindrical metal shells may vent gas. Proper pack-level thermal design and safety spacing are important.

These issues do not prevent their use, but they must be addressed through good system-level design.

4. How to Choose: A Practical Decision Guide

Choosing between 18650 and 26650 is mainly about matching the battery to your core requirements.

Step 1: Space and Energy Requirements

If your product has limited space and needs high energy density, 18650 is usually the better choice.

If space allows a larger diameter and you want higher capacity per cell to reduce the number of parallel cells, 26650 is a strong option.

Step 2: Discharge Needs and Cost

For applications that require high current or high power, such as power tools or fast-moving drones, high-rate 18650 cells are recommended.

For applications that focus on medium-rate continuous discharge and long runtime, such as energy storage or lighting, 26650 cells often provide better value.

For cost-sensitive, high-volume projects, the mature 18650 supply chain usually offers more competitive pricing.

Application-Based Summary

Choose 18650 when designing:

Portable consumer electronics

Lightweight electric mobility products

Power tools or devices with high power demand

Choose 26650 when designing:

Energy storage systems

Long-runtime lighting solutions

Products with enough space and strict capacity requirements per cell

Conclusion

18650 and 26650 batteries are not competitors, but complementary solutions.

The 18650 dominates portable and high-performance applications thanks to its excellent standardization, energy density, and cost advantages.

The 26650 holds a strong position in energy storage and long-runtime applications due to its higher single-cell capacity and durability.

When making a decision, move beyond the simple question of “which is better.”

Return to the basics of product design:

What are your space limits, energy needs, discharge requirements, and cost targets?

Once these questions are answered, the right battery format will become clear.