Battery 101: The Basics

Q1: What is the difference between Li-ion, LiFePO4, and LiPo batteries?

A: Each chemistry offers unique advantages: NCM/NCA Li-ion has the highest energy density for portable electronics; LiFePO4 offers the longest cycle life (2000-5000+) and superior thermal safety for ESS/EVs; Li-Po is most flexible in shape for wearables.

Q2: What do Voltage (V), Capacity (Ah), and C-rate actually mean?

A: These are core pillars: Voltage determines power potential; Capacity is the “fuel tank” size; C-rate is the speed of charge/discharge (e.g., 10C means a full discharge in 6 minutes).

Q3: What is a BMS and why is it essential?

A: The BMS is the “brain” that monitors health and safety, protecting against over-charge, over-discharge, short-circuits, and overheating. A pack without a quality BMS is unsafe.

Q4: How do I calculate the required battery capacity for my device?

A: Formula: Required Capacity (Ah) = [Device Power Consumption (Amps) x Desired Runtime (Hours)] / 0.8. The 0.8 factor accounts for a 20% safety margin.

Q5: What is the “memory effect” in modern lithium batteries?

A: It is a myth for modern lithium. Unlike old Ni-Cd batteries, Li-ion and LiFePO4 can be charged at any state without harming capacity.

Q6: How does temperature affect battery performance?

A: Cold reduces effective capacity and increases internal resistance, while excessive heat accelerates chemical degradation. We recommend operating between 15°C and 35°C for optimal life.

Engineering & Customization

Q1: What are your capabilities in custom BMS communication protocols?

A: We support full-stack development for SMBus, I2C, HDQ (real-time data) and industrial protocols like RS485, RS232, and CANBus for high-voltage systems.

Q2: Can you design battery packs for extreme temperature environments?

A: Yes. For low temps (-40°C), we use special electrolytes and heating films; for high temps (+85°C), we implement advanced thermal management and wide-temp cells.

Q3: How do you ensure cell consistency in multi-cell packs?

A: We use strict grading: ΔIR ≤ 2mΩ, ΔV ≤ 5mV, and ΔC ≤ 1%. Automated sorting ensures highly matched groups to prevent premature failure.

Q4: What specific information is needed for an accurate quotation?

A: We need your: 1. Application, 2. Voltage/Capacity, 3. Max continuous/peak current, 4. Dimensions (L×W×H), 5. Connector/Certification requirements.

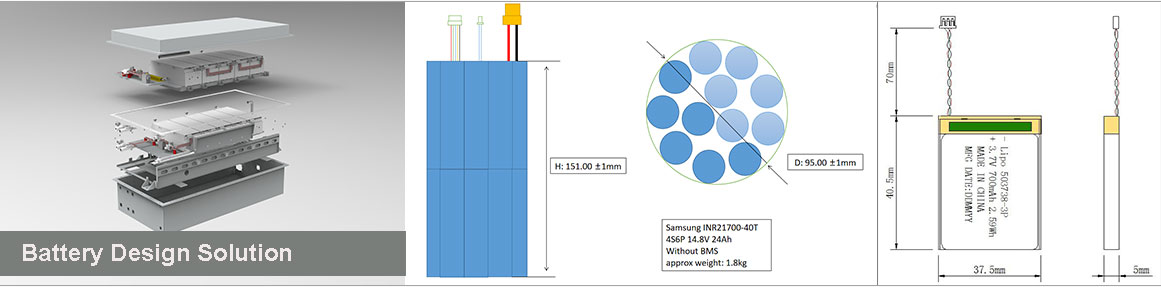

Q5: Do you provide 3D models for mechanical integration?

A: Yes. We provide detailed STEP or IGES 3D models and 2D drawings for your mechanical team to perform virtual fit-checks.

Q6: Can Himax handle parallel and series connection for scaling power?

A: Yes. We design our BMS to handle balancing across multiple strings and can advise on the maximum number of modules that can be safely connected.

Quality & Safety

Q1: How do you prevent thermal runaway?

A: Through multi-level protection: high-quality ceramic separators, advanced BMS monitoring, and 100% aging/vibration testing before shipment.

Q2: What traceability systems do you use?

A: Each pack has a unique QR code linked to our MES database, allowing us to track cell batch, BMS version, operator ID, and FQC data.

Q3: What is the standard FQC (Final Quality Control) process?

A: Beyond 100% aging, we perform BMS functional tests, load simulations, communication verification, and impedance checks.

Q4: How do you manage component supply chain quality?

A: We only source key components (ICs, MOSFETs) from authorized Tier 1 distributors like TI, Infineon, and Seiko to avoid counterfeits.

Q5: Is Himax electronics ISO 9001 certified?

A: A: Yes. We are ISO 9001:2015 certified (Certificate Number: 19820QL2386R0S), ensuring a process-driven approach to quality and continuous improvement. Query website: http://cx.cnca.cn/CertECloud/index/index/page

Certifications & Compliance

Q1: What international certifications can you provide?

A: We support UL, CE, IEC 62133, PSE, KC, and UKCA. All batteries pass UN38.3 for safe transport.

Q2: Do you assist with the custom pack certification process?

A: Yes. We prepare technical documentation, submit samples, and manage the laboratory relationship (TUV, SGS, etc.) to ensure smooth approval. https://www.tuvsud.com/en-us/store/academy-us , https://www.sgs.com/en

Q3: Are batteries RoHS and REACH compliant?

A: Yes. All products strictly comply with RoHS 3 and REACH environmental regulations.

Q4: Do you support Conflict Minerals compliance (CMRT)?

A: Yes. We conduct due diligence to ensure cobalt and 3TG minerals are sourced from conflict-free regions.

Q5: Can you provide the MSDS and UN38.3 reports for my shipment?

A: Absolutely. These documents are generated for every product model and are included in your shipping documentation package.

Shipping & Logistics

Q1: Can you handle DDP (Delivered Duty Paid) shipping?

A: Yes. We offer DDP to the USA and Europe, handling all freight, customs clearance, and duties for a hassle-free experience.

Q2: How do you ensure safety during air/sea freight?

A: We adhere to IATA and IMDG rules, using UN-certified cartons and anti-short-circuit packaging.

Q3: What documents are provided with the shipment?

A: Commercial Invoice, Packing List, MSDS, UN38.3 Test Report, and Shipper’s Declaration for Dangerous Goods.

Q4: How do you handle customs delays or inspections?

A: Our logistics team works directly with brokers to provide required data; if using DDP, we manage this entire process on your behalf.

Q5: Can I use my own freight forwarder?

A: Yes. We can work with your nominated forwarder and provide all necessary DG (Dangerous Goods) documentation for pickup from our factory.

Ordering & Partnership

Q1: What is your MOQ for prototypes vs. mass production?

A: Flexible: Prototypes can be 5-50 units. Mass production MOQs depend on materials but are always open to negotiation.

Q2: Do you sign NDAs to protect our design?

A: Yes. Protecting your IP is a top priority. We sign mutual NDAs before sensitive technical details are shared.

Q3: Can we audit your factory?

A: We welcome in-person or virtual factory audits. You can inspect our lines, labs, and QC processes.

Q4: What are your standard payment terms for B2B?

A: Typically 30-50% deposit with the balance due before shipment. We offer Net 30/60 for established partners.

Q5: Why choose Himax over a trading company?

A: We are a source factory with in-house BMS R&D and manufacturing control, not just a middleman or simple assembler.

After-sales & Warranty

Q1: What is the standard warranty period?

A: 12 months standard. Long-cycle LiFePO4 projects can be extended to 24-60 months based on requirements.

Q2: What is your RMA (Return Merchandise Authorization) process?

A: Contact your rep with the serial number. We diagnose remotely first; if needed, we issue an RMA for analysis and replacement.

Q3: Do you provide integration troubleshooting?

A: Yes. Our Field Application Engineers (FAEs) assist during your integration phase to identify root causes in the battery or device.

Q4: How should we store batteries if our production is delayed?

A: Store at 15-25°C at 40-60% SOC. Avoid full charge/discharge for long periods; refresh charge every 6 months.

Q5: Do you support battery recycling?

A: Yes. We provide material composition data to help your local certified recyclers process end-of-life batteries responsibly.

Industry-Specific Applications

Q1: [Medical & Robotics] How do you handle high-reliability and peak current demands?

A: For Medical and Robots, we implement redundant BMS protections and high-rate cells. For robotics, our BMS can handle peak discharge currents of up to 10C-15C to support motor start-ups.

Q2: [Marine & Exploration] How do you protect batteries from harsh outdoor environments?

A: For Boats and Exploration Equipment, we provide IP67/IP68 waterproof enclosures and use anti-corrosion connectors and internal potting to resist salt spray and heavy vibrations.

Q3: [IOT, Security & Communication] How do you maximize battery life for remote devices?

A: For IOT, Security Systems, and Communication Equipment, we optimize for ultra-low quiescent current in the BMS, ensuring minimal self-discharge during long standby periods.

Q4: [Wearables, Toys & Displays] Can you provide ultra-thin or flexible shapes?

A: For Wearable Devices, Displays, and Toys, we offer Li-Po custom shapes (curved, round, ultra-thin <1mm) and use high-energy-density materials to fit limited spaces.

Q5: [Energy Storage & Lighting] Why use LiFePO4 for UPS and solar systems?

A: For Energy Storage, UPS, and Lighting, LiFePO4 is ideal due to its 10+ year life and inherent safety. We include RS485/CANBus for easy integration with solar inverters.

Q6: [Micro Drones] How do you minimize weight without sacrificing power?

A: For Micro Drones, we use high-energy-density cells and eliminate unnecessary casing weight, using FPC instead of heavy wiring to maximize flight time.