Designing Batteries That Survive Where Others Fail

Hello, I’m Joan, a senior battery solution engineer at Himax Electronics, with over ten years of experience in lithium battery system design.

Today, I’d like to explain how we actually choose the right battery cell for your product, and more importantly, why this process directly affects your product’s performance, reliability, and cost.

At Himax, we believe this very strongly:

A battery solution is only as good as the cell selection behind it.

Cell selection is not a catalog exercise—it’s a structured decision-making process that starts from your product, not from the battery.

Our goal is simple but demanding:

to find the best balance point between performance, size, weight, safety, lifetime, and cost—so the battery becomes a strength of your product, not a limitation.

Let me walk you through how we usually approach this in real projects.

1. When your product needs very high power output

If your product needs strong, instant power—such as power tools, starter batteries, robotics, or high-performance drones—we immediately know that not all lithium cells are suitable, even if their capacity looks attractive on paper.

In these cases, we focus on high C-rate power cells, designed to deliver large currents safely and repeatedly.

For example:

- A standard 21700 energy cell offers 5000mAh but only supports safe 1–2C discharge rates.

- Power-focused models such as the Samsung 30T or Molicel P42A carry lower nominal capacities, yet deliver 30–45A continuous current with minimal voltage drop and no thermal runaway.

We analyze:

- Your peak current demand

- How long that peak lasts

- How often it happens during normal use

This ensures the cell doesn’t just meet the specification once, but maintains stable performance over hundreds of cycles, preventing issues like weak torque, sudden shutdowns, or early battery aging.

In short, we make sure your product feels powerful not only when it’s new, but throughout its life.

2. When battery space is very limited

Many modern products—smart devices, compact instruments, embedded systems—give us very little space for the battery. Here, the challenge is not chemistry, but geometry.

Our question becomes:

“How do we fit the right amount of usable energy into this exact space?”

We start by mapping your available volume and comparing it against:

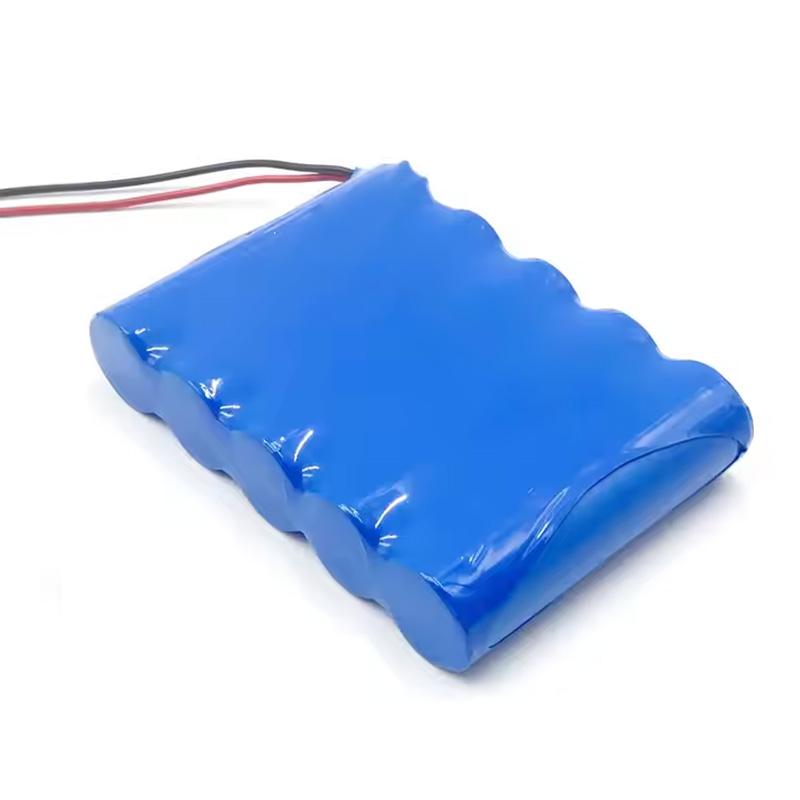

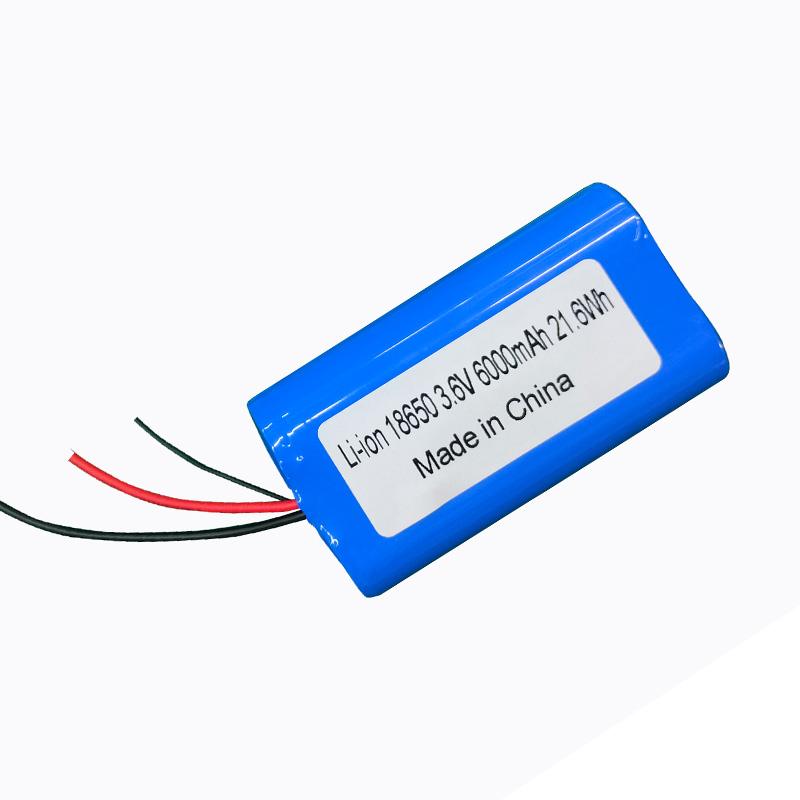

- Cylindrical cells (18650, 21700)

- Prismatic aluminum-shell cells

- Lithium polymer pouch cells

For example:

- Custom Li-polymer pouch cells utilize 90–95% of thin, rectangular spaces.

- Rigid, boxed structures benefit from prismatic cells, which deliver higher volumetric energy density and superior mechanical stability.

- We optimize for standard cylindrical cells when tooling costs must be kept to a minimum, maximizing cost efficiency.

We are not chasing the “highest mAh cell”—we are chasing the highest usable energy inside your actual enclosure.

3. When you need to balance lightweight design with runtime or durability

This is very common in medical devices, portable analyzers, handheld professional equipment, and premium consumer products.

Here, the key decision is often the battery chemistry, not just the size.

For example:

- High-energy NMC/NCA lithium-ion cells

O Lighter weight

O Longer runtime

O Ideal when portability and endurance matter most

- Lithium iron phosphate (LiFePO₄) cells

O Heavier for the same energy

O Much longer cycle life

O Higher thermal stability and safety

O Better for products with frequent daily use or harsh environments

We don’t decide this alone—we discuss with you:

- How often the product is used

- Expected service life

- Temperature conditions

- Whether safety or weight is the top priority

This way, the battery chemistry supports your business model, not just your hardware.

4. When your product shape is unconventional

Product design today is no longer a simple box, and batteries must adapt.

We regularly work with:

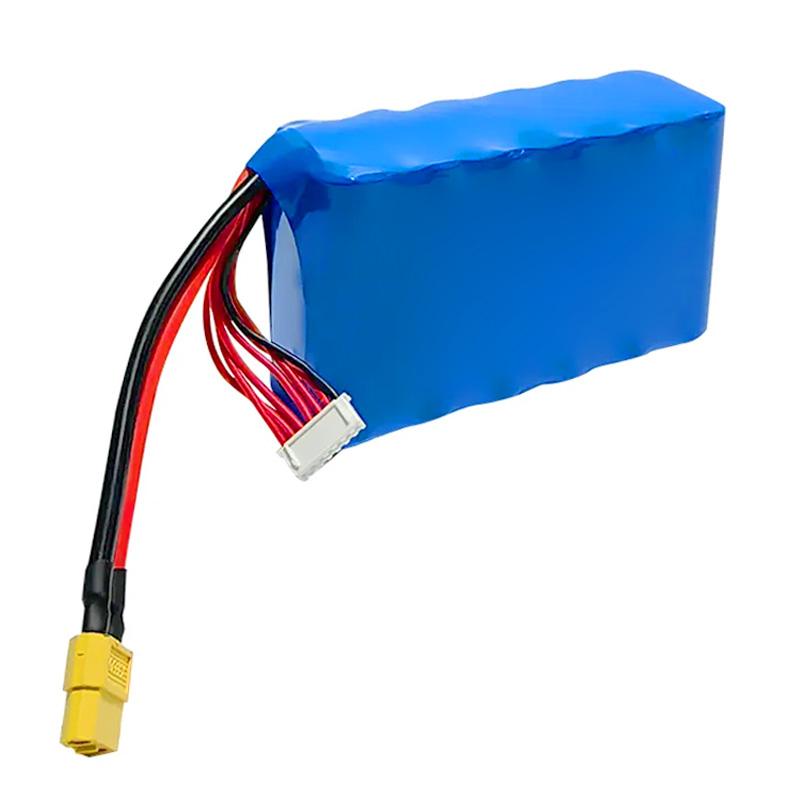

- Cylindrical cells(18650, 21700) – cost-effective, mature, easy to source

- Prismatic hard-case cells– high energy density, strong structure

- Pouch (Li-polymer) cells– flexible shape, thin profiles, custom layouts

For example:

- Stacked pouch cells excel in curved housings or layered internal designs

- Prismatic cells are preferred for products requiring maximum mechanical robustness

- A design focused on fast assembly and scalability may favor standard cylindrical formats

By matching cell shape to product structure, we improve:

- Space utilization

- Heat dissipation

- Mechanical reliability

- Overall safety

Bringing everything together

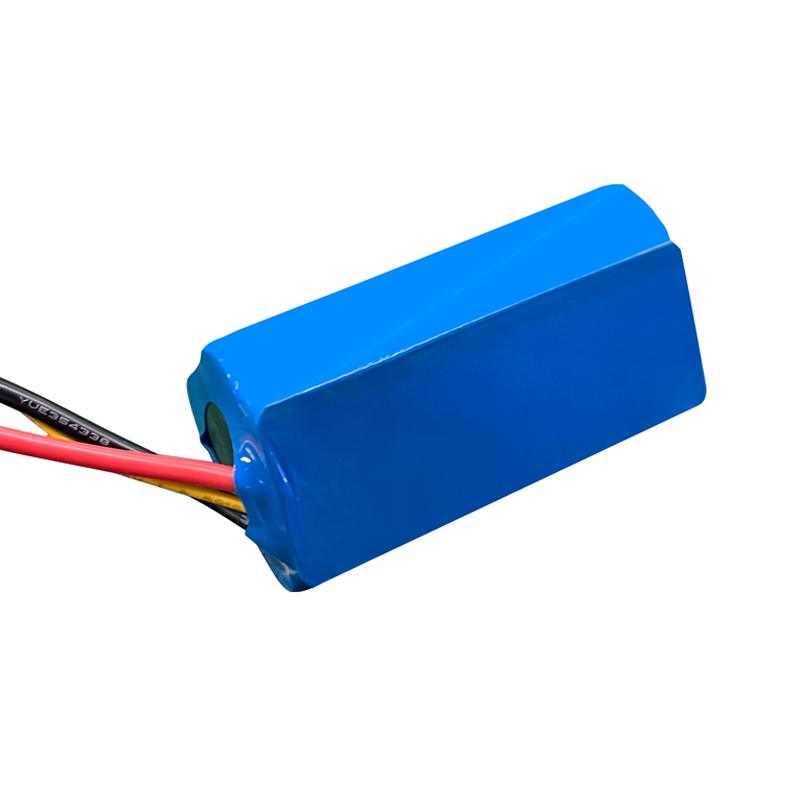

All these cell decisions are not made in isolation. They flow into a complete battery pack design, including:

- Properly matched BMS

- Electrical and thermal protection

- Mechanical structure and insulation

- Compliance with safety and transport standards

At Himax, we don’t believe there is a “best cell” in general.

There is only the most suitable cell for your specific product and market.

That’s why we see ourselves not just as a battery supplier, but as a technical partner—helping you turn the battery from a standard component into a real competitive advantage.

If you have a product concept or project in progress, we’d be glad to walk through it with you and provide a focused, practical cell and battery solution proposal.

Thank you for your time.