Why the “Box” Is Actually the First Line of Defense — and a Brand Statement

Hello, I’m Aliden, senior product design and mechanical engineer at Himax Electronics.

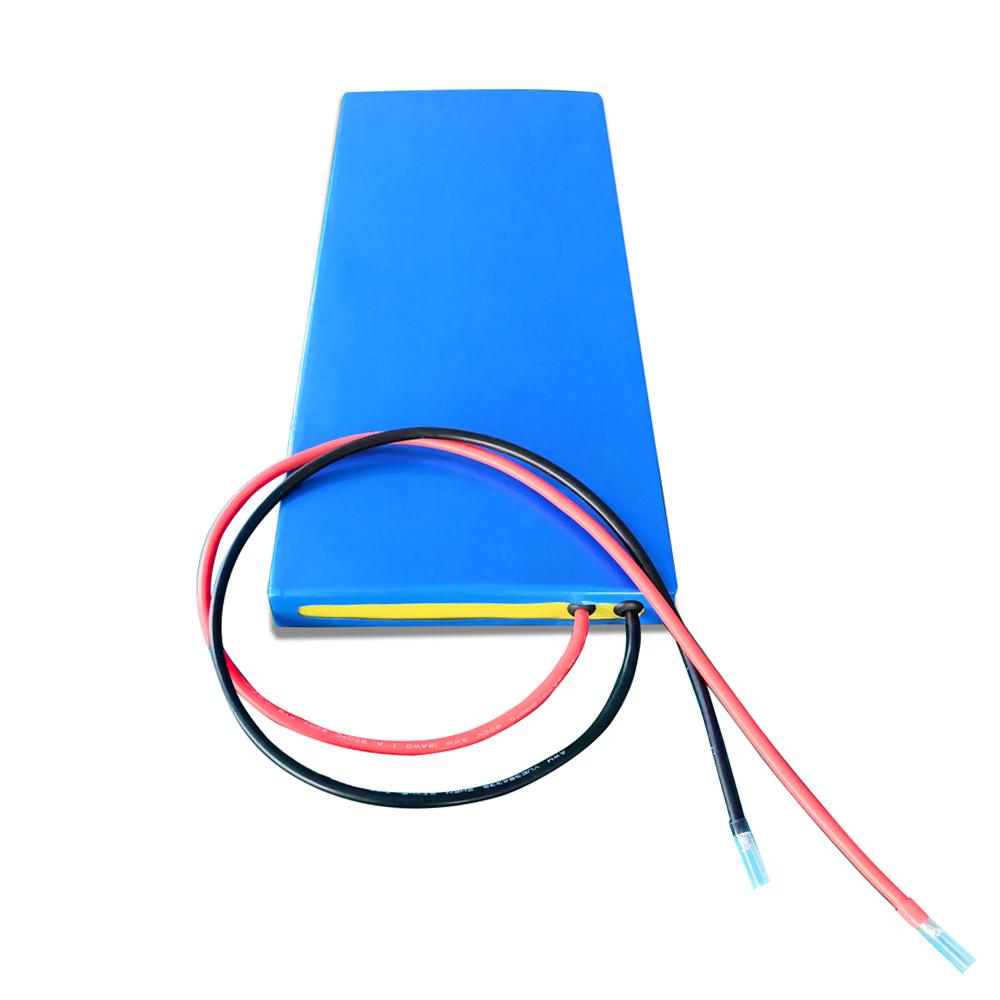

When customers receive a battery pack, the very first thing they see and touch is not the cells, not the BMS—but the enclosure.

From an engineering perspective, the battery enclosure is far more than a simple box.

In fact, it serves as:

- A safety fortress

- A thermal management component

- A structural backbone

- And a carrier of your product’s industrial design

How well this enclosure is selected and designed directly determines whether your battery system survives real-world conditions—and how your end users perceive your product.

Common concerns we hear from customers

Before diving into solutions, let me ask a few questions that many of our customers raise early on:

- Will the battery survive drops, vibration, water, or dust in real use?

- Is the battery enclosure taking up too much internal space?

- Can the battery design visually match the rest of the product?

- Are we over-designing the enclosure and paying unnecessary cost?

At Himax, our role is to act as an extension of your R&D team, Specifically, we translate your application environment, industrial design intent, and cost targets into the most appropriate enclosure solution—whether that is a proven standard option or a fully exclusive custom design.

How we match and design the “right” battery enclosure for your product

1. Meeting environmental and safety challenges: choosing the right “armor”

What you gain:

A protection strategy tailored to your actual application—not generic assumptions.

Different products face very different environments.

For instance:

- Outdoor energy storage, power tools, or industrial devicesoften require strong impact resistance and high ingress protection.

-

Medical or laboratory equipment, on the other hand, prioritizes cleanliness, stability, and controlled environments.

- Meanwhile, Vehicle-mounted or mobile applicationsmust survive continuous vibration and mechanical stress.

In practice:

- For dust- and water-resistant requirements, we often recommend high-strength engineering plasticssuch as PC or PC/ABS, combined with sealing gaskets, ultrasonic welding, or overmolding to achieve IP65–IP67 or higher.

- For harsher mechanical environments, we may move to sheet metal housings or extruded aluminum, reinforced with ribs and validated through vibration and drop simulations before physical testing.

Ultimately, the goal is simple: the enclosure should protect the battery exactly as much as needed—no more, no less.